Indonesia

Breadcrumb navigation

Employee Productivity Improvement (OTRS10)

Time and Motion Study, Kaizen innovation

OTRS is a work analysis and optimization software that helps reduce working hours, labor, and production and manufacturing costs through motion analysis and time analysis of videos.

Concept

Developed based on industrial engineering to support the improvement activities of your business OTRS can be utilized at all stages of the kaizen cycle.

| Analysis at the production site | Increase the efficiency of your continuous improvement program through performing time and motion analysis directly on site |

|---|---|

| Kaizen innovation | Utilize OTRS as a standard tool for driving improvement efforts across production, office and management functions |

| Connect and expand | Utilize OTRS in conjunction with other systems through enhanced data sharing |

Product Features

More precise measurements than ever before

Ability to process high frame rate video

Simple and easy to use

Immediately ready for use after installation

OTRS maintenance support package

Complimentary program maintenance and support for a full year

Online version updates

Regular version updates

Easy online updates

Advanced video engine for high-accuracy analysis

High frame rates ensure that not a moment in overlooked

- Analyze experienced technicians

- Analyze high-speed equipment

- Use in research applications

Rapidly visualize improvements within your production site

Eliminate Waste and Standardize processes

- Use simple operations to simulate the elimination of wasteful motion

- Use the frame-by-frame analysis feature to break down movements into segments for accurate analysis

Create Video Manuals

- Easy create video manuals from analysis results

Prepare Various Documentation

- Easily output work procedures, standardized work combination tables, operation balancing charts, and more

Train Staff and Transfer Technical Skills

- Effectively educate staff and transfer skills using the video comparison playback feature

- Make it easy for junior members to rapidly absorb training information

Simple design. Reach Features.

Motion Analysis

Easy operation via an intuitive graphical user interface.

Manual Creation

Quickly combine motion analysis results and create accurate simulations.OTRS Case Study

Reduction of operating costs

Identify and address non-value adding movement to reduce costs.| Before | After |

|---|---|

| Wasteful motion hidden in operations | Waste identified; labor costs reduced by 30% |

- Through breaking operations down into work elements, the value of each motion was determined allowing for minimization of waste and standardization of work. Resource requirements were then minimized through subsequently rolling out new standardized work operations,

In-house training

Transfer know-how from skilled technicians and improve the quality of employee training.| Before | After |

|---|---|

| Long time required for in-house training | In-house training time reduced by 50% |

- Comparing trainee movement against model technician movement made it easy to provide technical instruction, boosting training effectiveness. Self-study efforts also became more effective, greatly reducing the time required for staff training.

Standardization for a diverse workforce

Standardize work procedures and subdivide core tasks to address a broad range of staff labor needs and cater for a diverse workforce| Before | After |

|---|---|

| Variation in work time between staff | Staff average operating cost reduced by 15% |

- OTRS made it easy to divide tasks by element and optimize working hours by creating more flexible sift options.

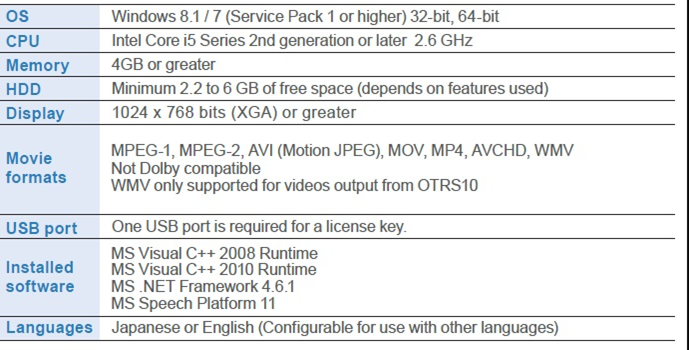

System Requirements

Contact Us

Enlarge Image

Enlarge Image