Indonesia

Breadcrumb navigation

Human Operation Navigation

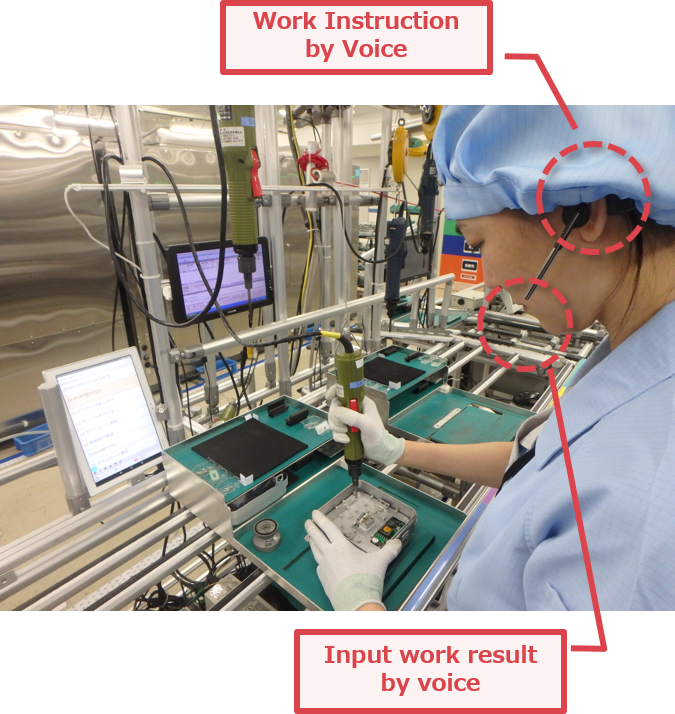

Confirm with ear, input by voice, improve efficiency of onsite-information communication

Digitalize human work at manufacturing site!

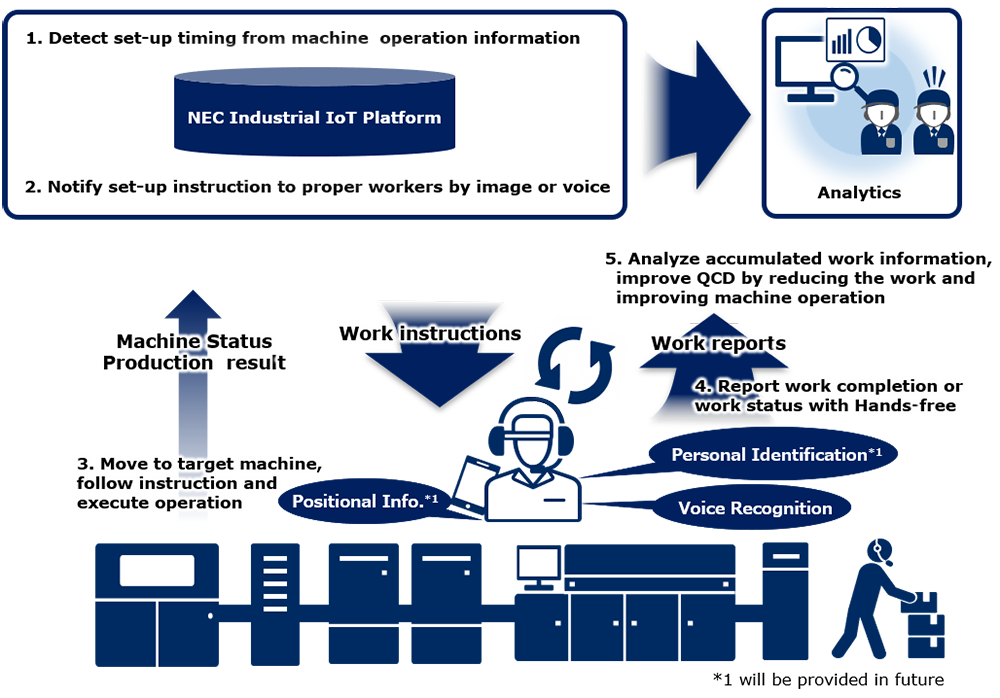

Navigate optimal workers at an optimal timing, optimize human work and improve productivity of the entire manufacturing site including production machines.

What is “Human Operation Navigation”

Human Operation Navigation optimizes manual operation and manufacturing control in a factory

| Work Classification | Benefit | |

|---|---|---|

| Routine work | Operation | Control |

| Assembly Work : Standardized work |

|

|

| Set-up Work : Switching work according to operation state | ||

| Inspection Work : Work with state measurement | ||

| None-routine work | Operation | Control |

| Abnormal Correspondence : Work depending on machine operation state ex)Machine failure maintenance |

|

|

Application effect

Improve inspection accuracy

Improve inspection productivity

Improve work and quality

Training period of standard work

by 25%

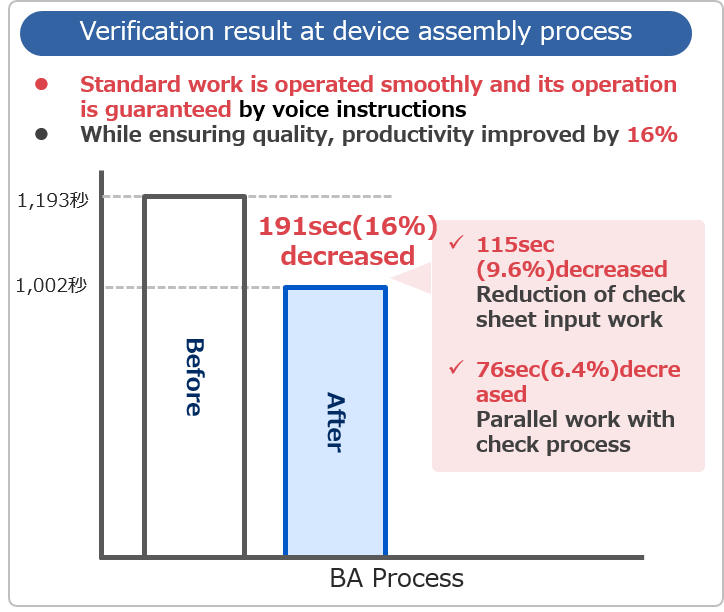

While Ensuring quality

by 16%

Improvement Cycle

40times

(1time a month → 2times a day)

Utilization

- Works in conjunction with NEC Industrial Platform and navigate proper worker at an optimal timing for human work triggered by an event occurred at manufacturing site.

- Reduce working time by hands-free report of work results, at the same time provide solutions for utilizing collected work results data.

Application Scene

Measures for demand fluctuation

Voice instruction+Work relay function

Voice instruction function of the standard work

Work in smooth by voice instruction.Once the error occurred, stop “Automatically”

Enlarge Image

Enlarge Image

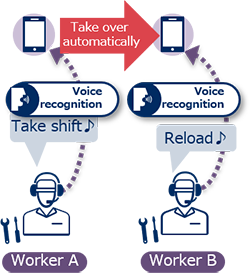

Work relay function realized by speech/recognition

Work instruction form will be taken over automatically,Realize Work relay.

Enlarge Image

Enlarge Image- Voice instruction following standard work

- Voice instruction stops when there is an error

- Work instruction form taken over automatically by speech

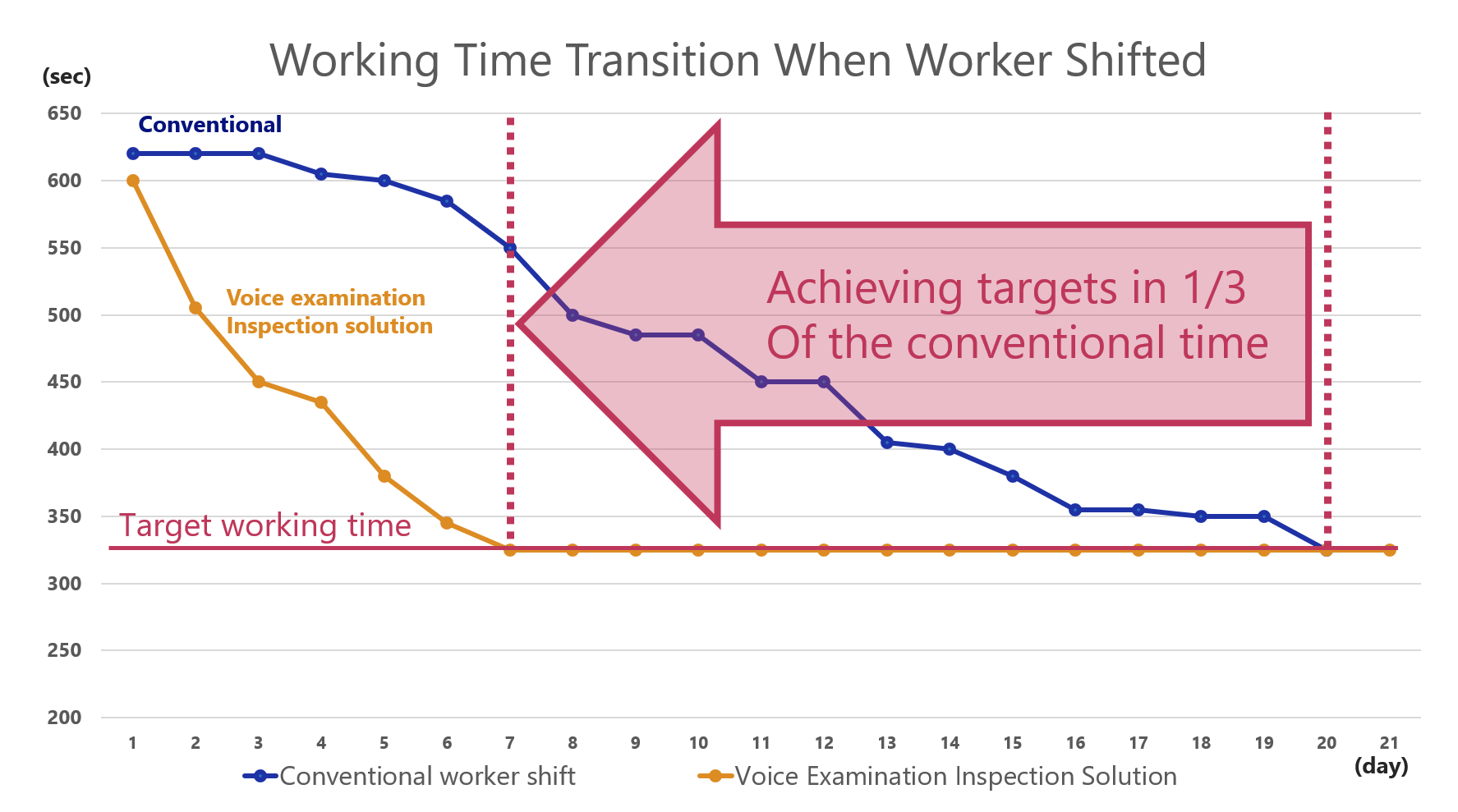

Trained workers in short term

- First-time worker trained in short term

- Design standard work procedure with voice instruction

- Realize stable cycle time

Quality cost control

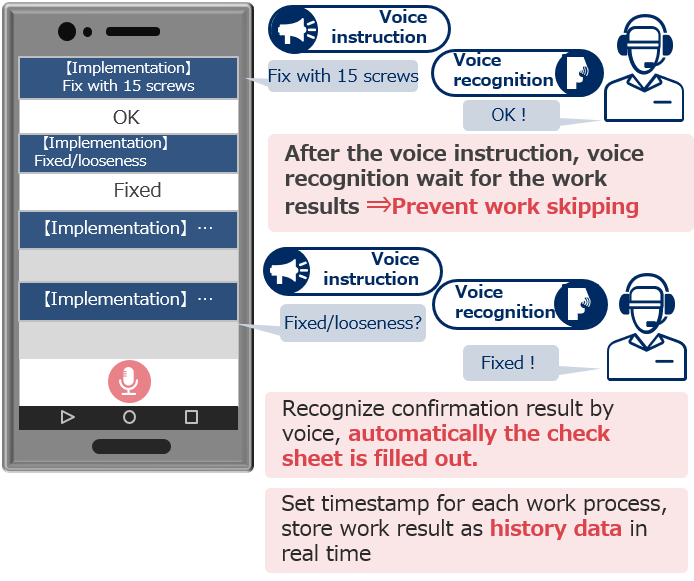

Collecting work result by Voice instruction+Voice recognition

- With voice instruction/voice recognition, prevent work skipping

- Fill out the check item automatically by voice recognition

- Store work result as history data in real time

Quality cost verification result

- Work in smooth by parallel check work

- Reduction of check sheet input work (paperless)

- Concentrating the work with keeping an eye on the product.

Functions/Characteristics

- Multiple language support

Support voice recognition and screen notation in multiple languages in order to support acceptance of overseas workers and overseas expansions of Japanese companies.

| Supported language | Japanese, English |

|---|

- Onsite worker can execute maintenance easily from web screen

Support voice recognition and screen notation in multiple languages in order to support acceptance of overseas workers and overseas expansions of Japanese companies.

Contact Us