Indonesia

Breadcrumb navigation

Warehouse Management System

-

Are the inventory quantity and numbers accurate?

-

Is it properly shipped according to the “FIFO” : first in, first out rule?

-

Why does inventory work take so long?

-

A defective Lot in stock has been discovered, and some have already been delivered!

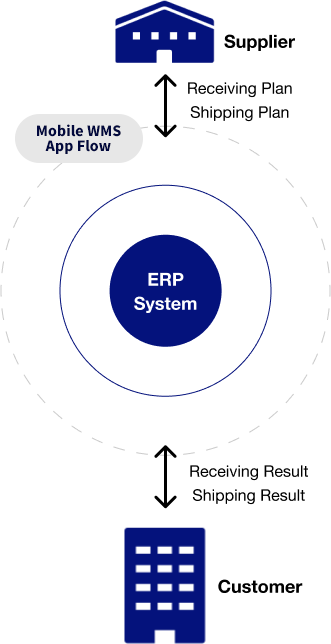

NEC offers you a flexible and mobile warehouse management system that answers the above challenges. With a simple mobile application to support the inventory management, you can have a reliable solution for your warehouse operation.

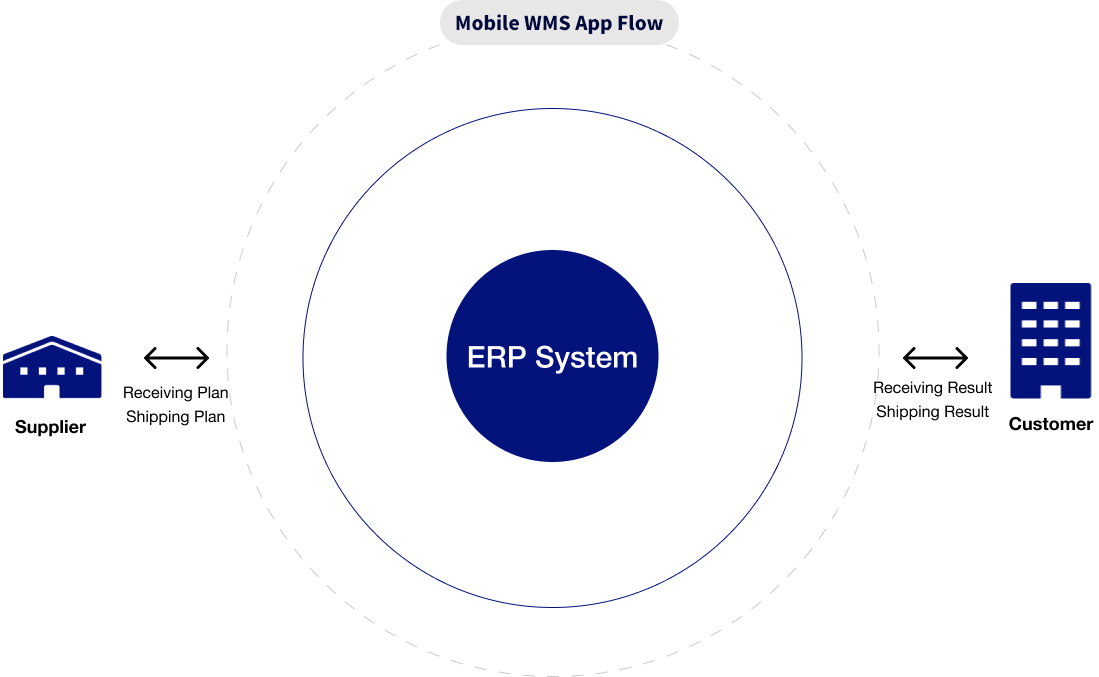

Inventory Management

Inventory Management

Create Plan and Book

Create Plan and Book  Print out FG Label

Print out FG Label Shipping

Shipping

Confirm Shipping FG

Confirm Shipping FG Receiving

Raw Material

Raw Material

Receiving Raw Material

Check for Receive

Check for Receive  Receiving by FIFO

Receiving by FIFO Receiving Finish Goods

Receiving Finish Goods

Picking by FIFO

Picking by FIFO  Receiving Finished

Receiving FinishedGoods from Production

Line to warehouse

Put away

& Storing

& Storing

Put away & Storing

Picking

Picking  Issue Material by FIFO

Issue Material by FIFO Production

Production

Major Scenario

Receiving + Identification tag

It is possible to manage not only the number of items in stock and the storage location but also the arrival date, expiration date, supplier, lot information, etc.

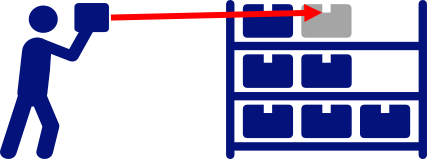

Picking / Inventory Transfer

You can match the information of the "picking list" output from “Mobile WMS App” with the information of the scanned “Identification tag" on the handy terminal.

Stock counting with Handy Terminal

The scan information will be sent to “Mobile WMS App” . Then, the quantity of the system inventory and the actual inventory are matched.

Key Features

Fast implementation with all Essential Inventory Functionality

NEC support customization in case of specific business requirement

Multi-Language Support (English and Indonesian)

Possible to select On-premise or Cloud

How to use?

Put-Away & Stored

Raw material or Finished Goods+Identification tag (QR/Barcode/RFID)

1

Input order data to “Mobile WMS App”

2

Print out identification tag with Barcode or QR Code or RFID

3

Attach the printed identification tag to all received item

Information including QR code For example: Receiving Date, Supplier Name, Item Number, Item Name, LOT No., Qty, Expire Date, Shelf Info, etc.

★ Instant information of the goods provided by WMS apps

Deliver to Warehouse

Put-Away & Stored

Deliver goods with identification tags to the suggested shelf

★ Quickly catch the shelf information of each product

Picking/Inventory Transfer

Enter the picking information in “Mobile WMS App” before shipping or issuing (follow the first-in, first-out rule)

Office

1

Input of

- Picking list

- Transfer information

- Issuing a picking transfer list

- Transfer list

Warehouse

2

Read

- Picking

- Transfer instruction information from the picking list by Handy Terminal

3

Check and Confirm

Scan the Office Identification tag by the Handy Terminal to check whether the Lot is correct or not.

As a result of scanning, picking the matching item, and carrying it out.

Contains information For example: The quantities of items to be picked, lot number, shelf number, destination, etc.

★ OK : Tag ID will show in the list and you will be notified by the sound effect “ping pong”

NG : The handy terminal body vibrates with a "boo" sound.

NG : The handy terminal body vibrates with a "boo" sound.

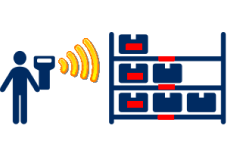

Stock Counting with Handy Terminal

The user confirms "system inventory" and "actual inventory" on the screen on “Mobile WMS App”.

For items that do not match the quantity, inventory adjustment will be performed using the inventory difference confirmation function.

For items that do not match the quantity, inventory adjustment will be performed using the inventory difference confirmation function.

Warehouse

1

Scanning for all item

Office

2

Confirm scanned results in the system

3

Adjust inventory in “Mobile WMS App” if there are differences

★ If the quantity does not match, adjust from the inventory result input / correction screen.

Contact Us